Discover our customised solutions

Discover a wide range of customised solutions at Alumat Zeeman, including tube, wire and sheet metal machining as well as robotic welding. With our years of expertise and advanced technologies, we offer high-quality industrial machining to meet the specific needs of the greenhouse sector and other industries.

High-quality industrial machining

Industrial machining? We have the right machines and the right professionals for it. Machining wire, sheet and tube is something we have been doing for years. Because of this, we also know that every product requires customisation. That is what we deliver. Particularly for the greenhouse horticulture sector, a sector in which we are the specialist as a producer of a wide range of components; both for the greenhouse, the ventilation system and the screen installation.

With Alumat Zeeman, you choose certainty. The certainty of the optimum finish with the right tolerances. In other words: for efficient production. Producing, for example, screen trays, covers and sealing corners is no problem for us. We are also at your service for additional operations such as welding.

Tube Processing

With its extensive machinery, Alumat Zeeman processes round, square and oval tubes. At our production site in Maasdijk, we have experience with pipes made of various materials, such as stainless steel, aluminium and (galvanised) steel.

Our specialisation is the rejuvenation of pipes for a seamless connection. During rejuvenation, the pipe ends are reduced in diameter, allowing two pipes to be connected easily. Rejuvenated pipes are widely used in horticulture in particular. This practical solution is universally applicable when pipes need to be connected on site. Besides horticulture, we also serve customers in, for example, stable construction and installation technology.

You can also come to us for crushing, punching and sawing tubes. In addition, we produce custom-made pushbuttons for your ventilation system. With our many years of experience, we are happy to advise you if you are looking for a complete screen installation or ventilation system.

Alumat Zeeman is your supplier for tube machining:

- Tube processing from 12 to 200mm diameter possible

- Various materials from stainless steel, aluminium to (galvanised) steel

- High-quality galvanised precision tubes (Contiflo) available from stock.

Wire processing

At Alumat Zeeman, wire processing is an art we master to perfection. Whether it is galvanised steel, stainless steel or spring steel, our CNC-controlled machines ensure a stunning end product. With technical drawings as our guide, your products are produced fully automatically with a precision that exceeds your specifications.

Our machines are true masters of wire machining, with a diameter range from 0.8 to 6 mm. Whether it's simple straight lines or complex bends, virtually any conceivable angle can be achieved with our advanced machining tools.

We understand the importance of reliability and precision in your projects. That is why we offer to make trial models based on your technical drawings, so you can be sure in advance that the end result will meet your expectations. And thanks to our large stock of wire, we can guarantee a fast delivery time so that your projects are not unnecessarily delayed.

Moreover, we guarantee careful packaging of your wire products so that they arrive to you handily and safely.

Choose Alumat Zeeman as your partner in wire machining and experience perfection in every detail.

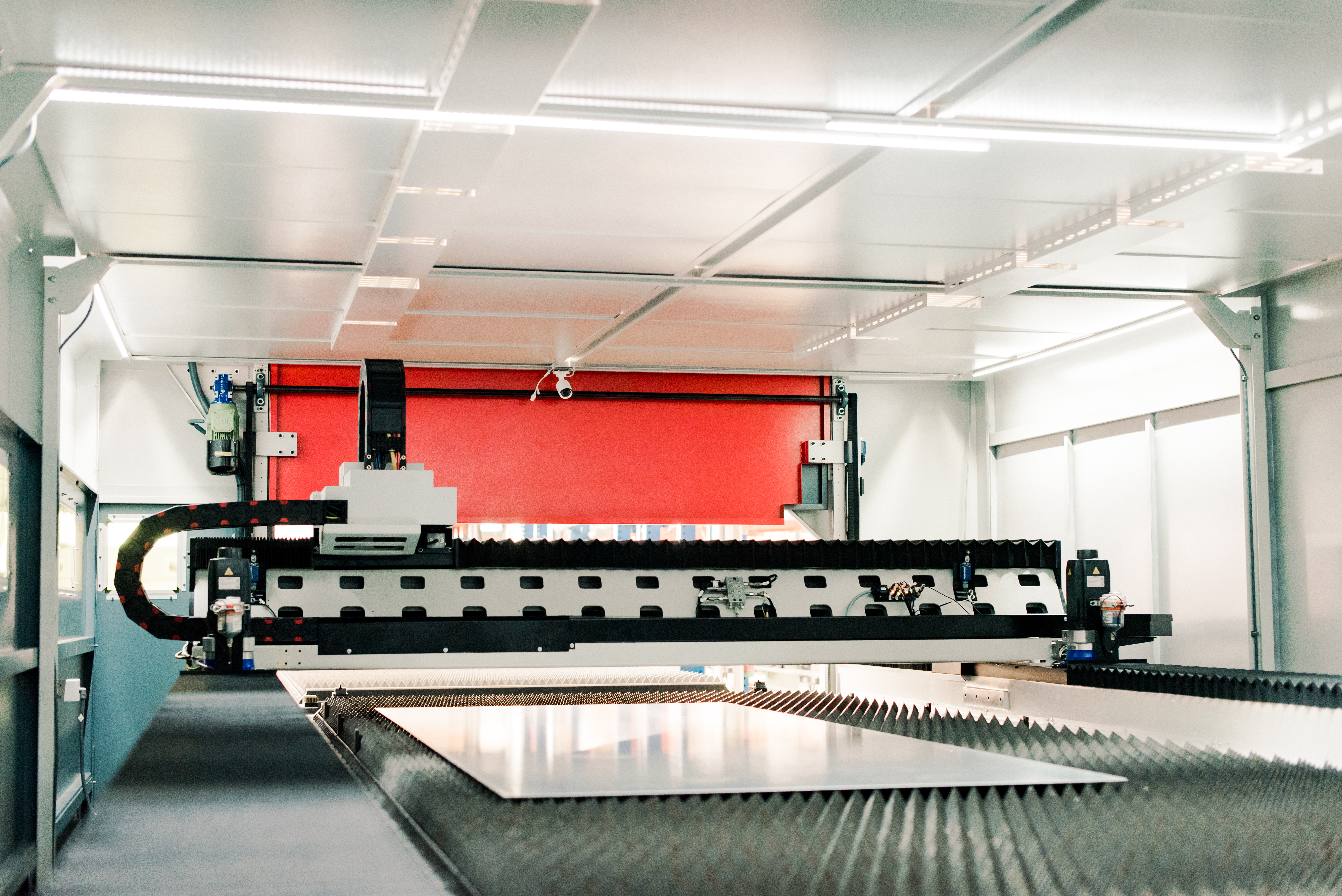

Sheet metal processing

At Alumat Zeeman, we understand the unique needs of professionals in the horticultural sector, which is why we offer an extensive range of sheet metal fabrication to perfectly match the requirements of your projects. Our state-of-the-art machinery allows us to machine sheets up to 6 metres long, with options including cutting, setting, punching and laser machining, all tailored to your specific needs and project requirements.

Specifically for horticulture, we offer the ability to produce U- and V-shapes for various applications, including screen boxes. These shapes are essential for creating solid and functional structures in greenhouses and horticultural environments. With our bending machines, we can convert sheet material accurately and consistently, enabling us to provide bending in any shape.

For our customers, we offer a total solution. Besides producing screen boxes and other sheet products, our experienced craftsmen can perform additional processing, such as welding and machine cutting. This way, you will receive a complete product ready for use in your horticultural projects.

With our expertise and state-of-the-art equipment, we can realise almost any design required for your projects. Whether it's simple straight shapes or complex customised structures, at Alumat Zeeman you can be assured of craftsmanship, precision and reliability in every aspect of your sheet metal operations.

Robotic Welding

At Alumat Zeeman, we push boundaries in efficiency and precision with our advanced welding robots. At our production site in Maasdijk, we have two of these high-tech machines, which can weld any product to perfection. The use of welding robots guarantees not only unprecedented speed in production, but also consistent quality that meets the same strict tolerances, regardless of the size of your series.

Robotic welding offers a range of advantages, including unparalleled precision and reliability. Our experienced craftsmen guarantee expert operation of the robots, ensuring that your products are manufactured with utmost care. Whether it is pipe and wire machining or other repetitive work, we are your reliable partner for providing high-quality welding solutions.

Choose Alumat Zeeman as your robotic welding partner and experience the benefits of fast production times, consistent quality and accurate results. With our skilled personnel and state-of-the-art technologies, we ensure that your welding is of the highest standards. Let us take your production to new heights with our robotic welding solutions.

We have an answer to any question

At Alumat Zeeman, we have the craftsmanship that is essential for optimal industrial machining. Craftsmen who know exactly what is possible with materials. Specialists who know exactly what is currently happening in greenhouse technology. Our knowledge and experience is also yours. You can count on a reliable and well-founded answer to your question.

We don't shy away from a complex question either. And with our expertise, we are not only the ideal industrial processor for the greenhouse horticulture sector, customers from other sectors also appreciate the craftsmanship of Alumat Zeeman. For example, we regularly have orders from the facade construction, agricultural sector, installation technology and machine construction industries. We also have the best solution for your industry.

Honderdland 32

2676 LS Maasdijk

The Netherlands

T+31 (0)88 4000 800

Esales@alumatzeeman.com

Route via Google Maps

This map is disabled because of your cookie settings.